北京博远瑞航科技有限公司

Beijing Boran Technology Co., Ltd.

MX800 and MF800 saw-blade processing machine is two PCD saw-blade grinding and trimming machine with unique design concept.Multi-axis CNC machine tool and stepless speed regulating grinding head can realize electrical discharge processing of various tooth profile PCD circular saw blade.

Self-research control system

It adopts advanced industrial grade computer, with LCD touch screen, and legitimate version of WINDOWS CE operating system. Combined with EDM grinding CNC software of gap-filling humanization design which is independently researched and developed, the machine tool is controlled.

Automatic turning compensation

In the processing process, the loss of electrode wheel can be set in advance, and it can be compensated by turning again in the processing process, so as to avoid inaccurate machining precision due to the electrode loss in the processing process.

All the operation processes are not only convenient and fast, but also effectively improve the precision of the saw-blade. Multi-tooth tool can be completed one time automatically without human intervention in the machining process.

Numerically controlled tooth setting

Numerically controlled tooth setting technology greatly reduces the non processing time and increases the indexing accuracy.

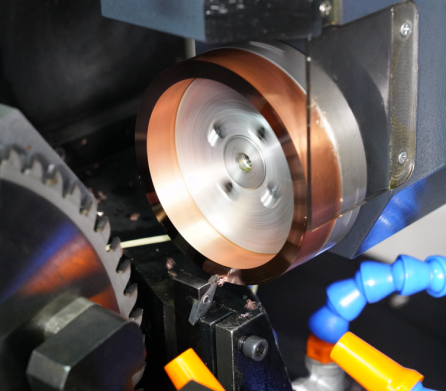

High-power rigidly precise grinding head

Pneumatic presser foot realizes stable processing of saw-blade. Reduction sleeve is used for the mounting of saw-blade. The simple and economic manual slide table expands the application space of the machine tool, which can process small saw blade, and can process big saw-blade. It can realize the turning function in the turning procedure segment, and avoid short circuit of copper cut.

The pneumatic system guarantees the stability of machining process. The transmission system is composed of Panasonic AC servo motor, PMI precise ball screw and precise linear guide-way, so as to ensure the accurate positioning.

Idling speed, processing speed adaptive adjustment fast back and forth, accurate and reliable movement positioning in a cycle can interrupt the processing of the teeth, chucked for one time and processed for one time.

Tooth-type library is rich and has the extension function. The sharpening is simple, and it reduces the operation difficulty to the maximum extent. There is no need to adjust the tooth spacing and basic thickness, with the function of jumping-over teeth processing.

Power supply and intelligent discharging gap control system

The innovative PCD dedicated and other energy pulsed generators strictly control the pulse width and pulse interval of the actual discharge, reduce the loss of electrode, and make the finished surface uniformity. Combined with intelligent discharging gap control system, the utilization rate of the pulse is increased to the optimum state, so as to make the processing efficiency, precision and finish further improved. In the processing process, the user can carry out CNC programming according to the actual demand, and the machine tool can automatically process according to the parameters and depth of the coarse, medium and fine processing set by the operator when the automatic processing starts.

Machine parameter MF800

|

机床参数Machine parameters |

||

|

X 轴行程 |

50 |

mm |

|

V1,V2 轴行程 |

40x40 |

mm |

|

W,U 轴行程 |

70x70 |

mm |

|

锯片加工精度 |

≤0.03 |

mm |

|

放电效率* |

0.2 |

mm/min |

|

刃口光洁度 |

≤Ra0.4 |

μm |

|

X,Z 轴行程 |

100x100x60 |

mm |

|

C 轴对轴心可旋转角度 |

±45o |

|

|

锯片加工精度 |

≤0.03 |

mm |

|

放电效率* |

0.2 |

mm/min |

|

刃口光洁度 |

≤Ra0.4 |

μm |